ALBAPLANT manufactures

CONTROLLED ATMOSPHERE FURNACES

IN TWO MODEL GEOMETRIES,

CHAMBER OVENS AND PIT OVENS

FOR SMALL TO LARGE VOLUME APPLICATIONS

WITH HIGH QUALITY STANDARDS.

IN A RANGE OF TYPICAL OR SPECIAL SIZES UPON REQUEST.

ALL TYPES CAN BE SUPPLIED WITH ELECTRIC OR GAS HEATING.

ALBAPLANT manufactures

CONTROLLED ATMOSPHERE FURNACES

IN TWO MODEL GEOMETRIES,

CHAMBER OVENS AND PIT OVENS

FOR SMALL TO LARGE VOLUME APPLICATIONS

WITH HIGH QUALITY STANDARDS.

IN A RANGE OF TYPICAL OR SPECIAL SIZES UPON REQUEST.

ALL TYPES CAN BE SUPPLIED WITH ELECTRIC OR GAS HEATING.

ALBAPLANT manufactures

CONTROLLED ATMOSPHERE FURNACES

IN TWO MODEL GEOMETRIES,

CHAMBER OVENS AND PIT OVENS

FOR SMALL TO LARGE VOLUME APPLICATIONS

WITH HIGH QUALITY STANDARDS.

IN A RANGE OF TYPICAL OR SPECIAL SIZES UPON REQUEST.

ALL TYPES CAN BE SUPPLIED WITH ELECTRIC OR GAS HEATING.

CONTROLLED ATMOSPHERE FURNACES

OUR RANGE

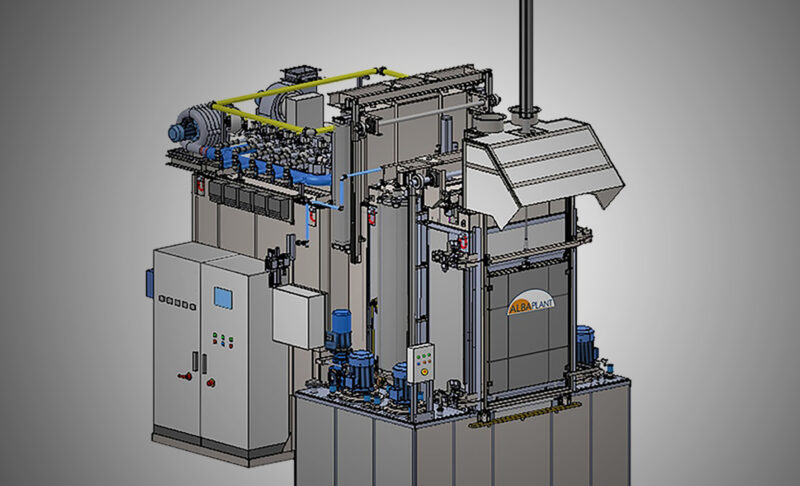

ALBAPLANT produces controlled atmosphere furnaces with high quality standards mainly in two model geometries, horizontal chamber furnaces and vertical shaft furnaces. Our range includes a number of models in standard sizes and special ones on request. Both types can be supplied with electric or gas heating. Albaplant’s standard furnace is equipped with the technical and performance characteristics that conform to automotive, aerospace and aeronautical market standards. Our software is not only very user-friendly, but also provides access to all special settings.

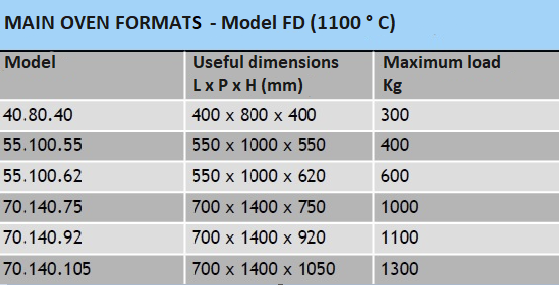

HORIZONTAL CHAMBER OVENS

TYPICAL TREATMENTS

• Cementation treatment

• Carbonitriding treatment

• Austenitisation treatment

• Hardening in oil, polymer or protective atmosphere

• Annealing, normalising, stress relieving and tempering treatments.

• Nitriding and nitrocarburizing treatment

FEATURES

• High level of repeatability and process security

• Exclusive regulation and control system

• Continuous analysis of the process chamber atmosphere and automatic regulation of technical gases.

• With the delivery you get our know-how from decades of experience in the industry.

• High level of reliability and safety of control panels and heating elements.

• Our plants can be supplied with a CQI9 Compliant control system on request.

• Emissions to current standards.

WHAT YOU GET

• Process repeatability and reliability

• Immediacy in reading information

• Low and easy maintenance

• Possibility of customising cycles ‘in house’

• Remote assistance and remote surveillance

COMPLEX AND AUTOMATIC LINES

ALBAPLANT designs and builds single plants and automatic lines all on a turnkey basis:

- Austenitisation Chamber Furnace

- Oil/polymer/salt hardening tank

- Preheating and/or Tempering Furnace

- Cryogenic Furnace (-120°C ÷ 300°C)

- Spray/immersion washing machine

- One- and/or two-storey storage banks

- Automatic loading/unloading shuttle

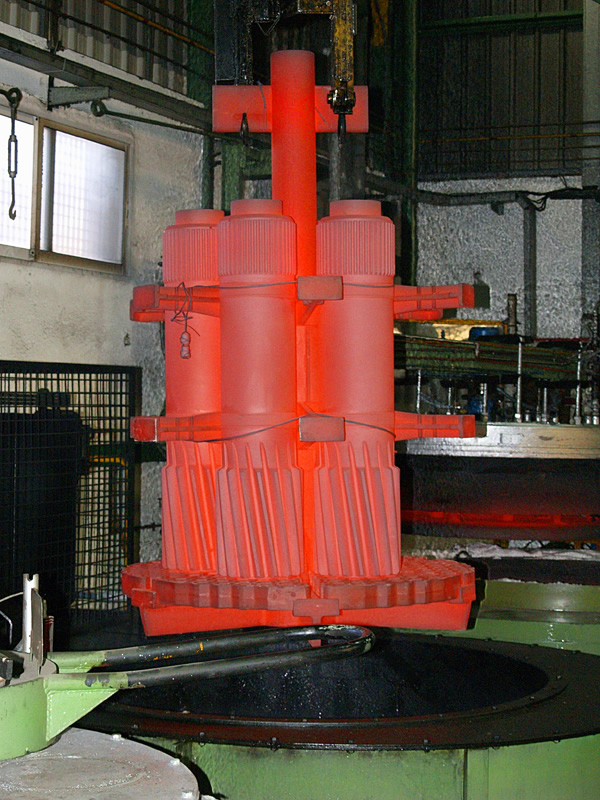

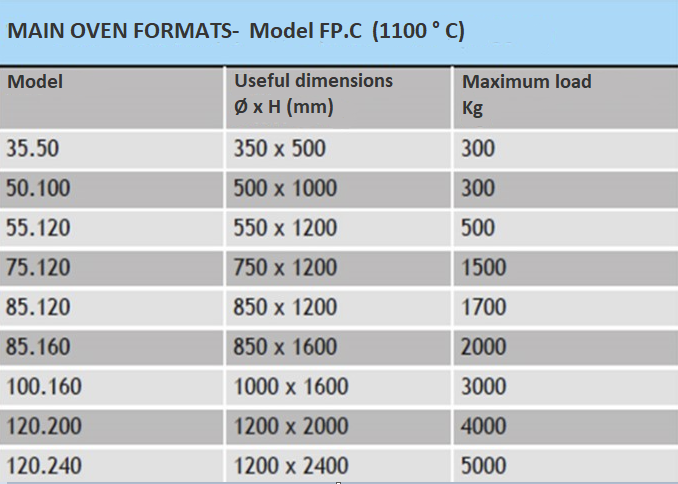

PITCH OVENS

ALBAPLANT designs and manufactures turnkey controlled atmosphere shaft furnaces that are much more than standard furnaces with controls. Our delivery is an integrated quality system that starts with evaluating with the customer the best application in accordance with their production requirements. . It then continues with on-site installation and commissioning, personnel training, process testing and the development of customised recipes. Our soaking pit furnaces are mainly Cementation, Nitriding and Cyclone furnaces for Stress Relief and Tempering.

CEMENT SOAKING PIT FURNACES

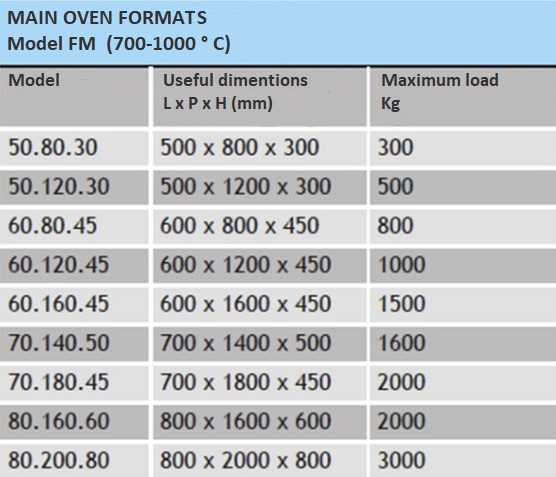

ALBAPLANT produces controlled atmosphere cement furnaces with high quality standards in a range of standard and special sizes on request.

The process control system developed by ALBAPLANT automatically analyses and continuously corrects the inlet flow ratios of technical gases, ensuring that the desired hardness settings are maintained.

The furnace is designed to operate fully automatically. The system via ‘PC’ allows total management of the charge being processed.

REINVENTION

and PRE-HEATING FURNACES

and PRE-HEATING FURNACES

We produce horizontal chamber and pit-type tempering furnaces with high quality standards for treatment in air or in an inert atmosphere, in a range of standard and special dimensions on request.

Typical applications include:

•Tempering Treatments

•Blank annealing

•Stress relieving and Normalisations

•Preheating

FEATURES

•Temperature uniformity with a tolerance of ± 3°C

•Temperature uniformity with a tolerance of ± 3°C

•Exclusive regulation and control system.

HIGH LEVEL OF REPEATABILITY

Our furnaces are designed to operate via ‘PC’ for total control of the process and the load being processed

Request information on ALBAPLANT products

Our technical experts are always available at Your disposal for any need